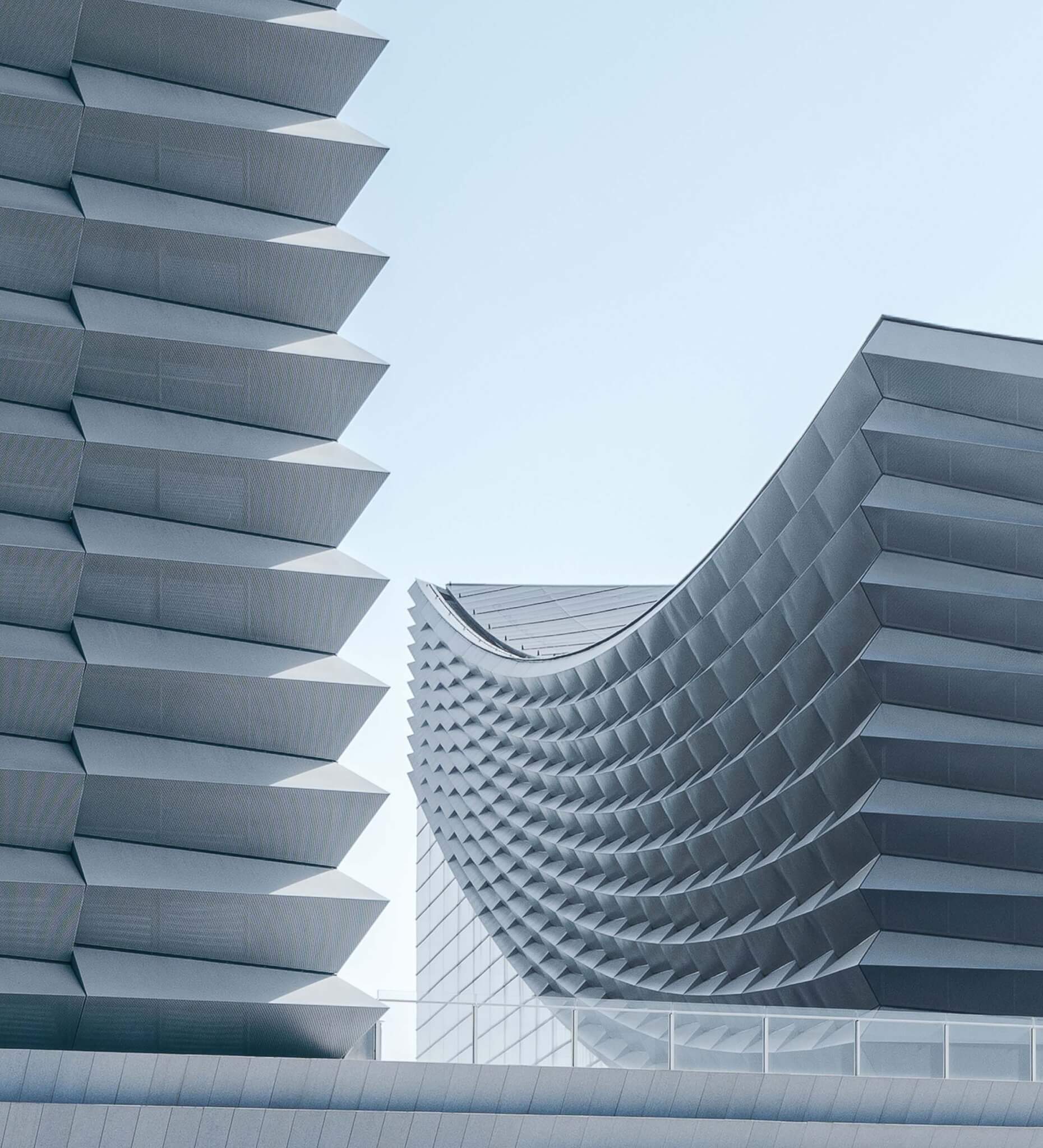

On the banks of the Grand Canal in Tongzhou, China, the eastern gateway to Beijing, Perkins&Will and Schmidt Hammer Lassen (SHL) designed a performing arts center comprised of three venues. While the three structures differ in scale from one another, they share a visual and material symmetry recognizable in their material application: Each of the three distinct volumes is expressed with a undulating, faceted profile, and the roofline forms recall the storehouses that once lined the banks of the waterway.

The architects originally envisioned using ceramic for the facade, but quickly found the material was too heavy and would require more structural support. They instead turned to aluminum. Not only is the metal lightweight, but it could also be fabricated locally. Across the campus, more than 4,300 aluminum panel components are on display.

The triangular aluminum modules are solid on top and perforated on their lower portion.

The triangular aluminum modules are solid on top and perforated on their lower portion.

Reflecting on the project’s sustainability metrics, Hardie noted that while aluminum has a higher embodied carbon than ceramic, the team’s use of thin sheets actually achieved a lower embodied carbon than what the ceramic would have delivered. In terms of embodied carbon for the overall project, Perkins&Will and SHL had targeted 500 kilograms of CO2e per square meter as the maximum. The completed building performed better than that goal totaling 390 kilogram of CO2e, and also surpassed local standards on thermal performance by a 20 percent margin.

The facade system was implemented across all three structures.

The facade system was implemented across all three structures.

For added strength on the lower portions of the facade system 5-millimeter aluminum sheets were installed, while for the areas of the facade more than six meters above the ground (approximately 19 feet) 4-millimeter sheets were used. Each of the aluminum modules has a triangular, tent-like shape, wherein the upper portion is solid and acts as a shading mechanism. The lower panel is perforated with 30- to 40-percent openness.

The unique shape of the facade system was refined in Rhino using Grasshopper. The architecture team shared the model and algorithm with the facade contractor as 2D drawings that were used to guide the digital fabrication process. On-site, the design team examined several mock-ups, paying close attention to the look of the perforation, as well as factors such as lighting and maintenance.

The design of the lobbies for each of the theaters is strikingly different.

The design of the lobbies for each of the theaters is strikingly different.

The pattern of the perforation is consistent across all facades. Several design and mechanical requirements compelled the need for the small holes: daylighting, air intake for equipment, and smoke extract in the case of fire.